Plasma Cleaning Machines

Plasma Cleaning Machines

Plasma, often referred to as the fourth state of matter, emerges as a revolutionary cleaning solution with versatile applications across a spectrum of materials, ranging from metals and glass to ceramics, wood, natural fibres, and textiles. In the intricate world of manufacturing, where processes like bonding, printing, painting, or coating play a pivotal role, the significance of surface properties cannot be overstated.

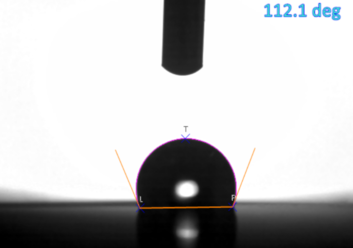

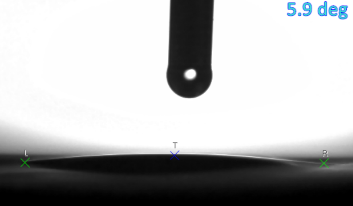

Achieving successful adhesion requires meticulous attention to cleanliness and wettability, aspects in which plasma cleaning excels. By elevating surface energy and forming molecular groups that optimize adhesion, plasma treatment proves to be an indispensable tool in the pursuit of enhanced wetting and surface optimization.

Analysing effect of plasma cleaning surface treatment

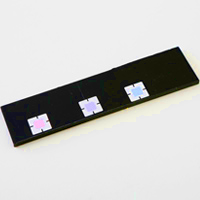

Additionally, our Tough Plasma FSI introduces a color-changing sticker for a more visual representation of plasma performance. By placing these 10×10 mm stickers on the surface to be treated and observing color changes (initially blue, transforming to pink upon plasma exposure), users gain valuable insights into the effectiveness of the treatment.

Applications of plasma surface cleaning in Industries

Our Atmospheric Pressure Plasma Cleaning Machines are tailored to meet the diverse needs of various applications across multiple industries:

1.Electronics Manufacturing

In this sector, our machines enhance the cleanliness of critical components such as semiconductor components, silicon wafers, lead frames, housing, wire bonding, and PCB molds. This, in turn, improves penetration and bonding for underfill, potting, and resin molds, contributing to the overall efficiency and reliability of electronic devices.

2.Medical Device & Life Science

Plasma cleaning is instrumental in eliminating residual contaminants in delicate medical instruments like surgical blades, catheters, and tubing. Additionally, it enhances biocompatibility in implants and stents, fostering improved patient outcomes. The technology also finds applications in improving adhesion for bioactive coatings, microfluidics, and various other life science applications.

3.Aerospace Manufacturing

The aerospace industry poses unique challenges, often involving large components with complex profiles and composite materials. Our Atmospheric Pressure Plasma Cleaning Machines address these challenges by ensuring thorough cleaning and preparation of aerospace components, contributing to the industry’s stringent safety and performance standards.

4.Automobile

Automotive applications include the application of Formed-in-Place Gasket (FIPG) and improving adhesion in hard-to-bond polymers found in rear doors, instrument panels, glass windows, bumpers, batteries, separators, motors, and other critical components. Plasma treatment replaces conventional methods like primers, flame, and corona treatments, offering a more efficient and environmentally friendly solution.

Materials traditionally known for poor adhesiveness, such as polypropylene and polyethylene, experience enhanced adhesion and reduced cohesive failure when treated with plasma. This versatile processing method stands as a testament to the innovation and efficiency that plasma cleaning brings to various manufacturing processes.

Key Technical Features of open air plasma cleaning machine

The success of our Atmospheric Pressure Plasma Cleaning Machines is attributed to their cutting-edge technical features:

Plasma Generation System

Plasma Nozzle

Real-time Monitoring and Feedback

Contact us for the price of plasma cleaning machine in India and evaluation tests

INTERESTED IN OUR PRODUCTS?